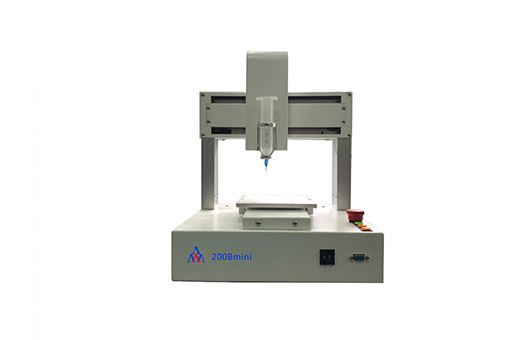

Equipment the fuselage is composed of sheet metal processing of the lacquer that bake, internal machined parts all through the CNC precision machining, to ensure the assembly needs to be planar and vertical degrees, all electrical part adopts domestic and foreign well-known authentic products, to ensure the stability of product quality, factory equipped with a large number of inventory standard machine for a long time, other non-standard machine size, can also accept customized, assembly processing time only 2 to 3 days to complete, large amount of discount.

Equipment Characteristic:

1. To replace manual dispensing operation to achieve mechanized production;

2 .Small occupation space, maximum saving of work space;

3. It is the easiest to operate and install a single machine;

4 .Chinese operation interface, easy to learn, easy to understand, simple and practical operation setting;

5. It has the functions of continuous interpolation of irregular curves such as dotted line, plane, arc and whole circle, three-axis linear linkage and 3D circular interpolation;

6. The software has functions of area array, translation and rotation calculation, etc.;

7. Support CAD format PLT format DXF file G code import;

8. According to the requirements of the production process, positioning PIN of the worktable and positioning fixture and precise dispensing valve heating device can be added;

9.The machine is equipped with needle setting button, which can complete needle setting without external instruction box;

Specificatios:

| Product Model | ARW-2205Bmini |

| Motion Range X/Y/Z axis(mm) | 200*200*50 |

| Max Load X/Y/Z axis(kg) | 3/3/2 |

| Translational Speed X/Y/Z axis(mm/s) | 300/300/200 |

| Repeatability(mm/s) | ±0.02 |

Program Capacity | Stepping motor in Japan+BGC |

| Direct Drive | 3Axis(3D space any route can be) |

| Display Mode | Hand box or LCD(optional) |

| Dimensions W*D*H(mm) | 340*340*440 |