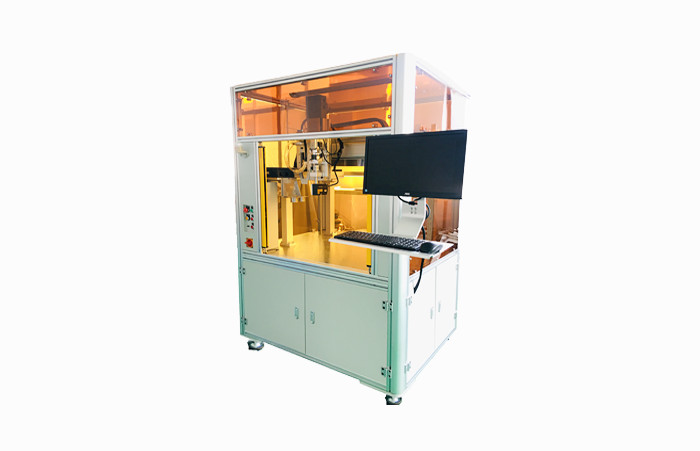

Applicable industry:Photoelectric industry FPC flexible board, PCB board IC chip butcher protection and bottom filling as well as CCD lens precision electronic components structure bonding and filling.

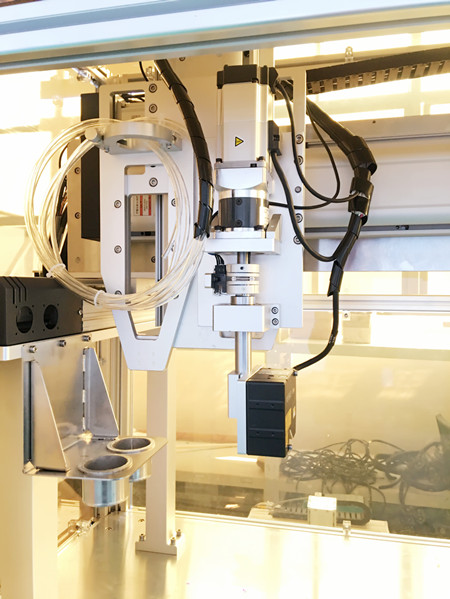

1, The image equipment can detect the position of the target dispensing product, correct the position of the target dispensing product, and then correct the motion trajectory of the manipulator to achieve the purpose of high-precision dispensing.

2, The traditional method of needle programming is changed. Instead of needle programming, images can be used to write instructional programs more conveniently and quickly. At the same time, the position accuracy of programming is greatly improved.

3, Array detection + dispensing programming is supported. CCD detection can be completed in the form of array, and then dispensing can be done in the form of array.

4, This method reduces the motion path and improves the efficiency of the glue.

5, Through the preset shortcut keys, it can easily switch between the image running mode and the needle running mode.

6, The product model and technical characteristics are the same as those of H series screw dispenser.

| Project | Content | Notes |

| Camera pixel value | 300,000/1.3 million/2 million/5 million | |

camera type | Contour search/edge position scanning (mainly for fixing point glue) | |

Defect inspection/appearance inspection (mainly used for post-dispensing inspection) | ||

| Code identification (bar code, two-dimensional code) | ||

| Single detection time | 70(Typical value) | Detection time + data communication time varies slightly according to the size of the image template |

| Dispensing accuracy | ±0.02MM | The actual dispensing accuracy, in addition to CCD images, is also related to dispensing process |

| Image stabilization time | 300 | From the moment the manipulator stops until the image can be detected stably |

Detection time | 70(Typical value) | Detection time and data communication time vary slightly according to the size of the image template |

Testing precision | ±0.03 | Depending on the camera, lens, and product size |

Photoelectric industry FPC flexible board, PCB board IC chip butcher protection and bottom filling as well as CCD lens precision electronic components structure bonding and filling.