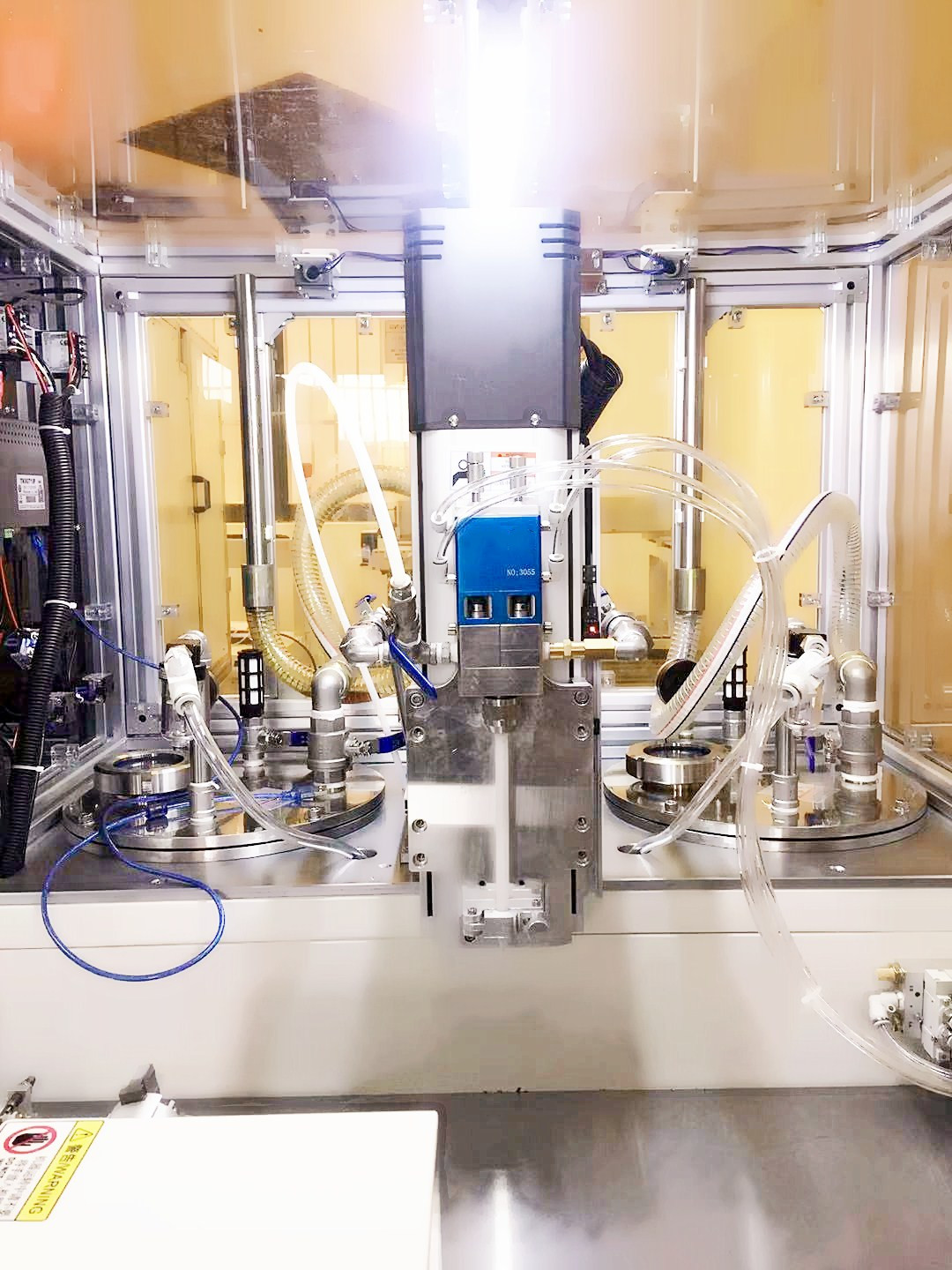

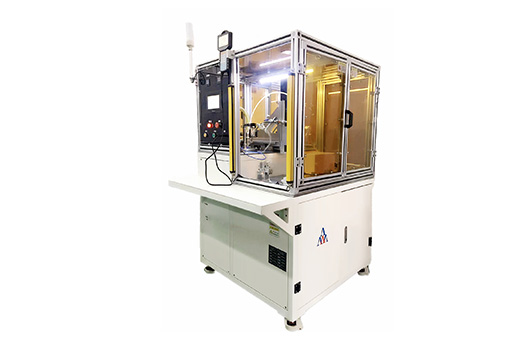

A two-component glue automatic quantitative control glue mixing and automatic equipment, the equipment is mainly embodied in the can apply to the different proportion of two-component, PLC as control core, made in proportion to the stepper motor control precision metering pump proportioning, ensure that the quality of mixing two kinds of glue, has obvious advantages of high performance, reliable, durable, compact design, suitable for more specifications of the products. Equipped with friendly operating software to ensure system stability and reliability.

The use of three-claw finger cylinder can improve the stability and accuracy of clamping cylindrical objects.

Adopt 2-pass rotating shaft, so that the air pipe will not be wound on the rotating shaft when the clamping cylinder rotates;

The use of built-in plastic bucket, maintain beautiful appearance, good sealing; Funnel-shaped bottom no residual glue, clean and tidy;

The use of hidden heating device, both safe and beautiful.

| Control system | PLC control, touch screen display, glue quantity, glue speed and other parameters set, can realize speed change glue function |

| Mixing system | Double stepping motor control metering pump ratio accurately, the proportion can be adjusted 10:100 |

| Mixed Systems | Dynamic/static mode (this device is dynamic) |

| Cleaning system | Two cleaning methods, gas and liquid, can clean the mixing device automatically |

Alarm system | Material cylinder is equipped with high and low level induction device, automatic alarm for material shortage and full; And equipped with stirring device, heating thermostat and vacuum defoaming function |

![]()